Steam TurbinesM+M Turbinen-Technik |

Backpressure TurbineOptimizing the use of your process steam with combined heat and power production. |

|

Product Information

With our robust and versatile M+M backpressure turbines, your process steam can be utilised more efficiently and sustainably. Instead of simply reducing the steam pressure at a pressure-reducing station, you can expand your process steam in the turbine and generate electricity. This combined heat and power (CHP) generation, significantly reduces the energy costs of your facility and contributes to a sustainable reduction in CO₂ emissions.

Turbine Parameters

|

Frequent fields of application

Condensing TurbineMaximum power generation from your steam with optimal efficiency. |

|

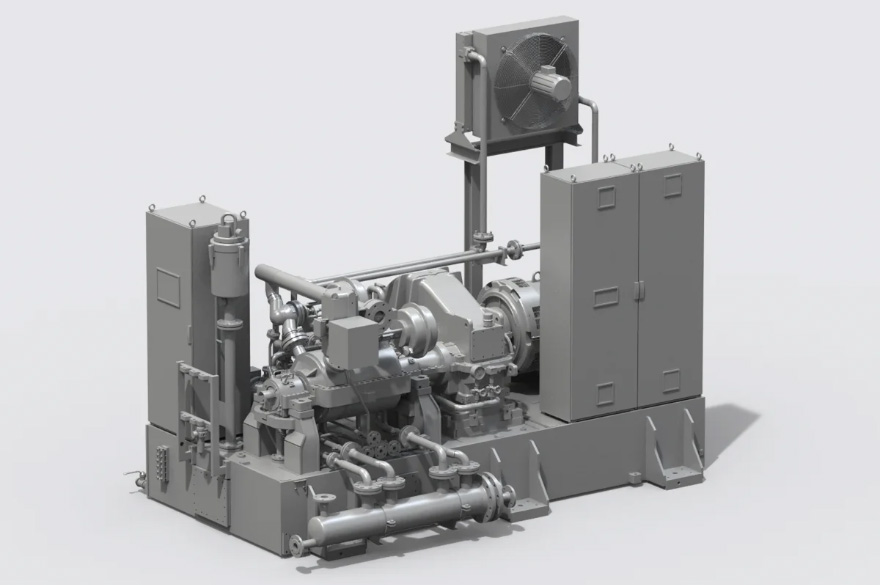

Product Information

Generate maximum electricity from your steam in our M+M Condensing Turbines. By using a flexible and multistage design, we achieve maximium power and efficiency in a condensing turbine. Through flexible design of steam bleeds and extractions, the overall process efficiency can be even further enhanced. Our solid design, based on the proven robust impulse turbine principle, ensures high availability, low maintenance costs, and thus, operational efficiency with our turbine. And this across a wide range of operating conditions.

Turbine Parameters

|

Frequent fields of application

Extraction TurbineOptimal Process Integration with our M+M Extraction Turbine. |

|

Product Information

In our M+M extraction turbines, a portion of the turbine steam is regulated and extracted as process steam. The remaining steam is expanded to the exhaust pressure for additional power generation. The extraction turbine can be combined into either a backpressure or a condensing turbine. With a customized turbine design, fluctuating process steam demands for each individual application can be fulfilled. This ensures a flexible and efficient balance between process steam supply and power generation. Multiple controlled extractions at different pressure levels in one turbine is easily achieved through M+M’s concept of individualized turbine design. A controlled extraction is possible at very high and very low pressure levels, including even an extraction in vacuum. Talk to our experts to explore the possibilities!

Turbine Parameters

|

Frequent fields of application

Induction TurbinePower generation with steam supply from multiple pressure levels. |

|

Product Information

In our M+M induction turbines, steam is supplied into the turbine at more than one pressure. (In principle, the turbine is supplied with two steam inlets: the ‘normal’ inlet and the ‘induction’ steam inlet.) This permits flexible efficient power generation to be integrated into an existing or complex process. The induction turbine can be combined with either a backpressure or a condensing turbine. With this customized turbine design, fluctuating plant steam demands for each individual application can be economically fulfilled. The induction turbine ensures a flexible and efficient balance between process steam supply/generation and power generation. Multiple controlled inductions at different pressure levels within one turbine is easily achieved through M+M’s concept of individualized turbine design. An induction is possible at very high and very low pressure levels, including an induction even in vacuum. Talk to our experts to explore the possibilities!

Turbine Parameters

|

Frequent fields of application

District-Heating (CHP) TurbineCombined heat and power (CHP) for optimal energy utilisation. |

|

Product Information

For applications where heat production is the primary goal, our District-Heating (or CHP) turbines are the ideal solution. Steam is expanded in the turbine for power generation and removed at the exhaust for heat production. By using the full condensing energy of the steam, the most efficient use of valuable energy resources is achieved – reducing your C02 footprint. Our turbines are individually designed to meet your specific application – for example, this includes considering the process demand profile across the entire year, not just at one single design point. It also means considering the potential use of a two-stage heat production, which can further maximize the efficiency. If desired, we can supply the heating condenser, ensuring that you receive a fully functional system supplied from a single hand.

Turbine Parameters

|

Frequent fields of application

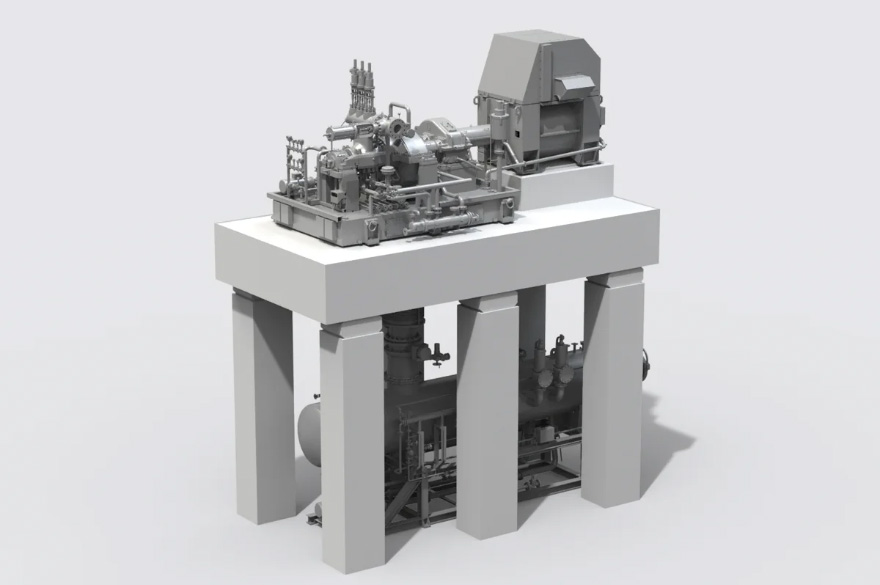

Mini-TurbineOptimal efficiencies: Even with minimal steamflow. |

|

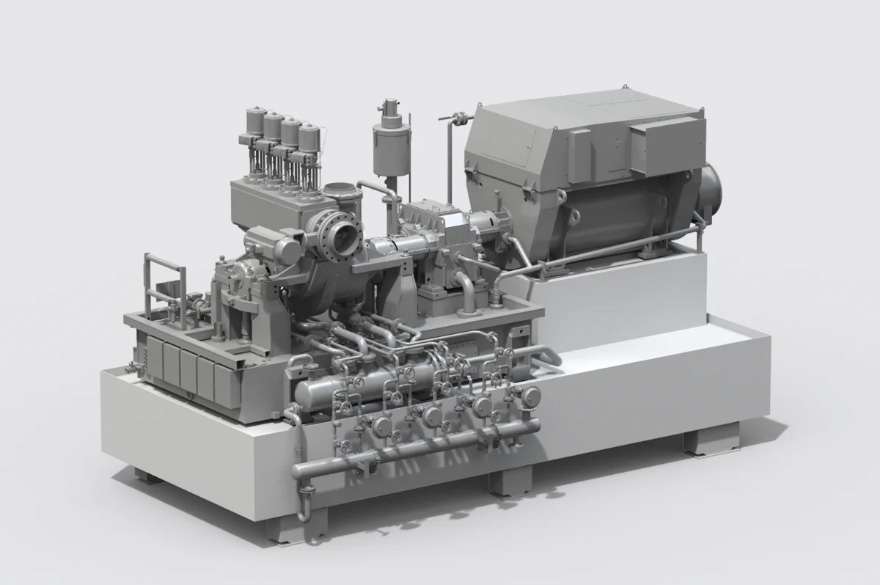

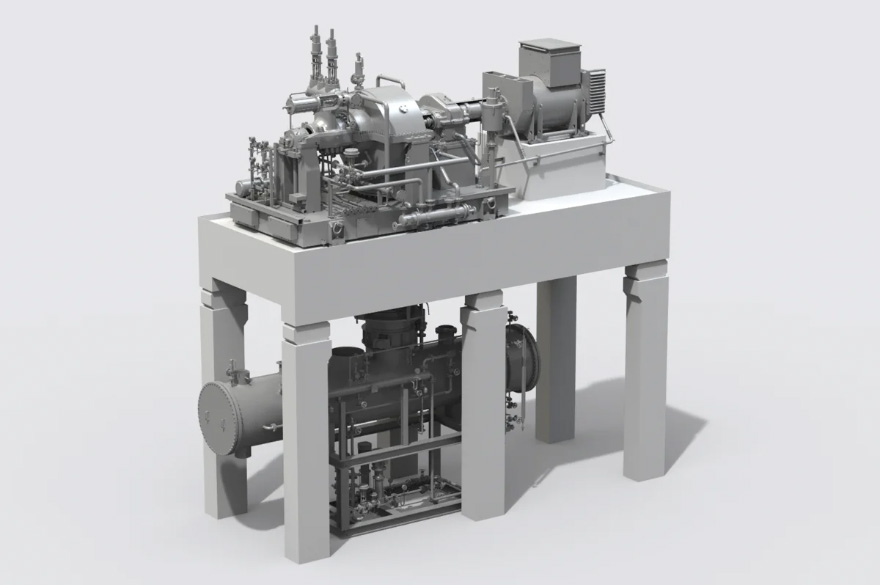

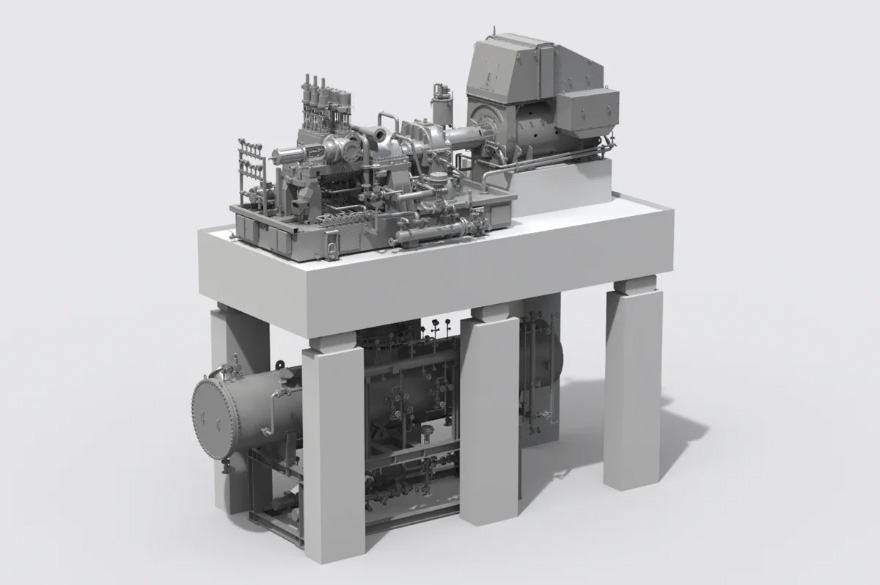

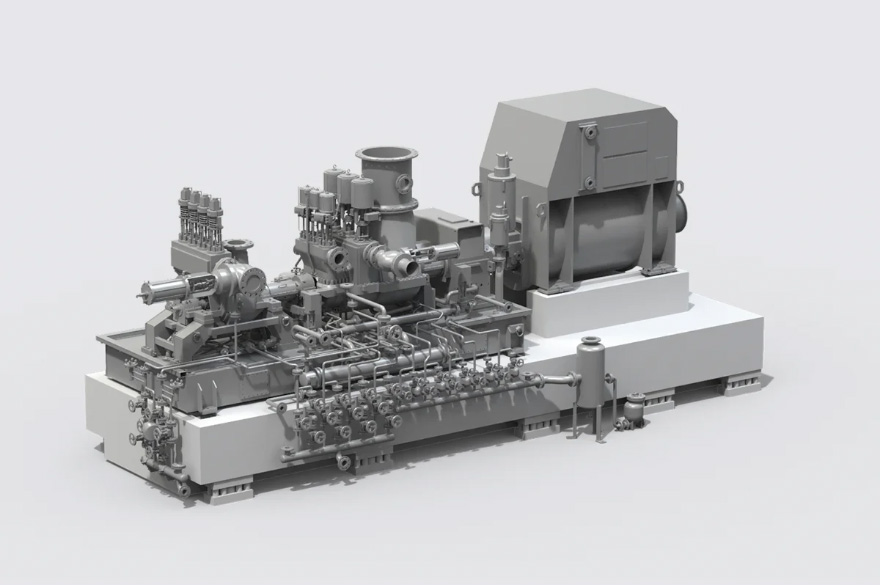

Product Information

Our innovative "Mini-Turbine" offers an economical and sustainable solution to efficiently generate electrical power from even the smallest quantities of steam. By combining our proven multi-stage design with a high-rotational speed, we achieve both a compact and cost-effective construction. All package components of our "Minis" are delivered on a single common baseframe as a "plug and play" solution, ensuring short installation and commissioning times at site.

Turbine Parameters

|

Frequent fields of application