Cooling Systems (CT’s and ACC’s)Paharpur portfolio is from small factory-assembled units up to large concrete cooling towers to be built on site, air cooled heat exchangers and air cooled steam condensers. Continuous design improvement to match customer requirements with the best materials and design techniques has led to the design and installation of mechanical draught towers in fiberglass, steel, wood and concrete with wood, plastic and concrete fill options and the development of hyperbolic natural draught towers. |

|

|

|

The broadest range of cooling towers designed specifically for rigorous duty in producing electricity, fertilizers petroleum refining, petrochemicals, chemical processes and general manufacturing may be seen in next photos: |

|

|

|

|

|

|

In what respects to air cooled heat exchangers Paharpur is recognized as a leader in this matter. |

|

|

Paharpur designs and manufactures air cooled steam condensers for any type of utilization. |

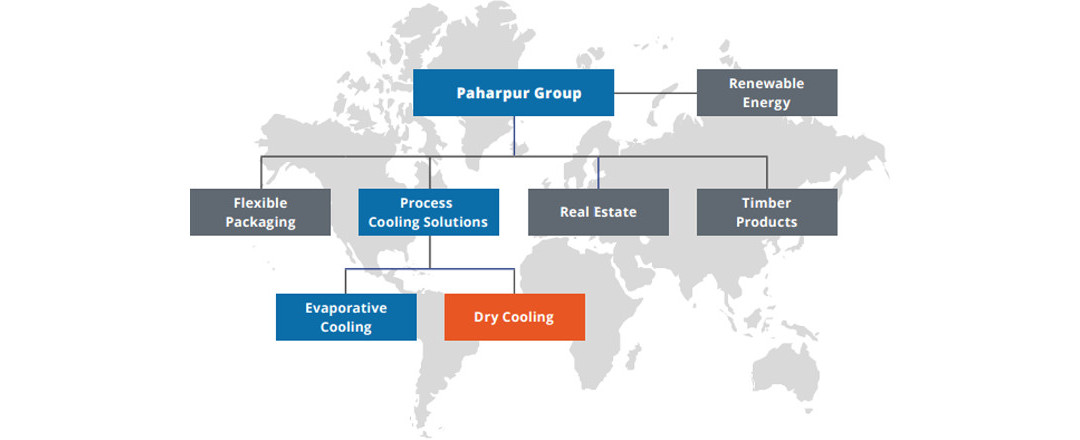

Process Cooling Solutions Dry Cooling |

|

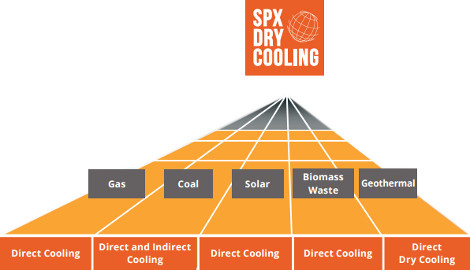

SPG Dry Cooling is a leading global brand in Air-Cooled Condenser design, manufacturing, construction and services. More than 1000 SPG Dry Cooling Systems for Combined Cycle, Coal, Natural Draft Condenser, Parallel Condenser System and Solar Power Plants have been installed around the world for a wide range of environmental conditions: coastal and desert climates, industrial and urban locations in both tropical and arctic temperatures. SPG Dry Cooling, with its fully owned heat exchanger manufacturing plants, maintains a world class reputation of reliability and efficiency in power generation and industrial applications for large and small size plants. |

|

|

DIRECT DRY COOLING SYSTEM FROM SPG DRY COOLING Traditional A-Frame, is the state-of-the-art Air Cooled Condenser (ACC), suitable for small to large power plant in a large variety of site conditions (low ambient temperature, high wind, high seism, low noise,…). |

Single-Row Condenser tubes (SRC®)

A-Frame ACC module Overview |

|

A-Frame ACC features The heat exchanger’s finned tube, the core technology of the Air Cooled Condenser, is the Single-Row Condenser (SRC®) tube – an elongated aluminum cladded carbon steel flat tube with brazed aluminum fins. The excellent corrosion and freeze resistant SRC® finned tubes are manufactured in SPG Dry Cooling fully owned state of the art factories. Heat exchangers are supported by an A-Frame structure which can be mounted on concrete or steel structure. Both primary and secondary type heat exchangers are provided to ensure good non condensable gas extraction to the air evacuation unit. Airflow is delivered by forced draft axial fans, driven by electric motors and gearboxes, installed below the heat exchangers. A-Frame ACC’s are available from 2 to more than 80 modules per unit and with fan size from 28ft to 38ft. The typical scope for an ACC installation includes the heat exchangers, the fan motor groups, the supporting structure, the steam ducting from the steam turbine interface, auxiliaries such as the condensate and drain pumps, condensate tank, the air evacuation units and related piping works, electrical and instrumentation – (see below). With over 200 SRC ACC installations, SPG Dry Cooling has extensive experience in designing, manufacturing, delivering and constructing A-Frame ACC’s all over the world. |

|

For more info about SPG Dry Cooling see here. |