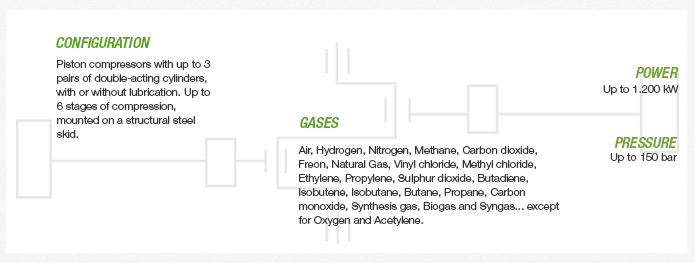

Specialized Applications

Enerflex builds onshore, as well as offshore compression packages for virtually any application and point in the natural gas cycle – at the wellhead, gathering system, processing plant, pipeline, storage facility, or re-injection/disposal well. Our packages are designed to handle virtually any gas inlet stream – including varying concentrations of CO2 and H2S. Our gas-fuelled drive engines can run on field gas that is high in impurities.

We will do what it takes to accommodate your inlet gas composition. Enerflex compression systems are engineered and built with a range of requirements in mind: safety, corrosion resistance, and condensation associated with compressing impure gas in cold-weather conditions. Where needed, our designs include insulated components, warm-up cycles using sweet gas, or various line heaters and heating coils. Our offshore packages contain the additional safety features required by industry standards for installation on platforms, as well as the specialized, corrosion-resistant marine coatings.

Some of our specialized compression applications are:

- At the Wellhead

We can provide booster compressors for both sweet and sour gas applications. Along with these, we also provide high-spec vapour recovery units (VRU’s) to capture gas that previously would be flared or vented from tanks and other well-site equipment. These VRU packages typically require lower HP and can utilize a screw compressor, reciprocating compressor or a rotary vane compressor.

- Gas Storage and CO2 Re-Injection

When you have high discharge and injection pressures, not just any provider can build a reliable and safe compression system. We can with custom-engineered solutions. We have operational packages running at high pressures for oil lift, enhanced recovery, and reservoir storage. These applications push the envelope in technology, engineering, and first principle stoichiometry.

- Refrigeration Compression

Motor-driven centrifugal compression is becoming more and more popular, and Enerflex provides custom-engineered solutions, typically in the 4,000 hp to 6,000 hp range. While screw compressors are common in refrigeration applications, Enerflex will also provide motor driven centrifugal compressor packages that are custom engineered for your needs. Typically these compressors are advantageous in 4,000 or more horsepower.

When choosing Enerflex, the result will always be a compression package that maximizes production and is reliable, safe, and long-life.

|